ShopJuly 17, 2025

-

Civil War Period Gentleman’s Smoking Cap

$350Civil War Period Gentleman’s Smoking CapJuly 17, 2025 -

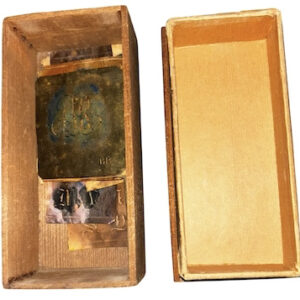

Id’d Stencil Kit of Gen. Bennet C. Riley (Last Military Governor of California, Veteran of the War of 1812, the Seminole War and the Mexican War

$450Id’d Stencil Kit of Gen. Bennet C. Riley (Last Military Governor of California, Veteran of the War of 1812, the Seminole War and the Mexican WarJuly 15, 2025 -

Civil War Period Man’s White Linen Shirt

$375Civil War Period Man’s White Linen ShirtJuly 13, 2025 -

Id’d Civil War Bullion Embroidered Infantry Officer’s Hat Badge – Major Levi Kent 9th Rhode Island Infantry

$750Id’d Civil War Bullion Embroidered Infantry Officer’s Hat Badge – Major Levi Kent 9th Rhode Island InfantryJuly 13, 2025 -

Civil War Period Massachusetts Volunteer Militia Officer’s Short Jacket

$2,250Civil War Period Massachusetts Volunteer Militia Officer’s Short JacketJuly 12, 2025 -

Pre-Civil War c. 1855-1860 Rifleman Officer’s Epaulettes

$800Pre-Civil War c. 1855-1860 Rifleman Officer’s EpaulettesJuly 10, 2025 -

Rare 1850s – 1860s Man’s Heavy Wool Cloak

$850Rare 1850s – 1860s Man’s Heavy Wool CloakJuly 9, 2025 -

Id’d Union Officer’s Frock Coat, Trousers, Sash and Belt – Lieutenant Henry Ward Camp 10th Connecticut Infantry – POW at Battery Wagner Assault and KIA at an Engagement on the Darbytown Road Outside of Richmond on Oct. 13, 1864

$17,500Id’d Union Officer’s Frock Coat, Trousers, Sash and Belt – Lieutenant Henry Ward Camp 10th Connecticut Infantry – POW at Battery Wagner Assault and KIA at an Engagement on the Darbytown Road Outside of Richmond on Oct. 13, 1864July 6, 2025 -

Id’d Virginia Style CS Tongue and Wreath Belt Plate – Capt. Lewis J. DuPree 45th Ga. Infantry and Post Surgeon at Griffin, Ga. – Plate is Accompanied by a Letter of Authenticity Handwritten by Steve Mullinax

$3,650Id’d Virginia Style CS Tongue and Wreath Belt Plate – Capt. Lewis J. DuPree 45th Ga. Infantry and Post Surgeon at Griffin, Ga. – Plate is Accompanied by a Letter of Authenticity Handwritten by Steve MullinaxJuly 5, 2025 -

Rare Civil War Period Id’d Sterling Silver Collapsible Cup in Original Moroccan Leather Covered Case – Created by Noted New York Silversmiths Wm. Gale & Son

$295Rare Civil War Period Id’d Sterling Silver Collapsible Cup in Original Moroccan Leather Covered Case – Created by Noted New York Silversmiths Wm. Gale & SonJuly 4, 2025 -

Id’d Chasseur Style Civil War NCO’s Kepi Cap – Sgt. Billings Hodgdon Co. B 5th Maine Infantry

$3,450Id’d Chasseur Style Civil War NCO’s Kepi Cap – Sgt. Billings Hodgdon Co. B 5th Maine InfantryJune 19, 2025 -

Civil War Period Dress Epaulettes of Col. Henry Larcom Abbot(t) of the 1st Connecticut Heavy Artillery

$1,750Civil War Period Dress Epaulettes of Col. Henry Larcom Abbot(t) of the 1st Connecticut Heavy ArtilleryJune 16, 2025 -

Civil War Period Cockades – Virginia Mourning Cockade and a Patriotic Cockade

Civil War Period Cockades – Virginia Mourning Cockade and a Patriotic CockadeJune 9, 2025 -

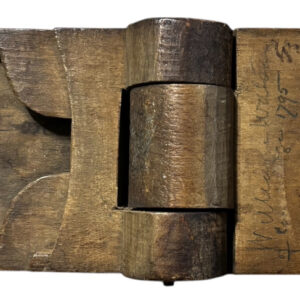

Unusual Handmade Folding Wood Traveling Bootjack Dated 1795

$325Unusual Handmade Folding Wood Traveling Bootjack Dated 1795June 6, 2025 -

1/6 Plate Tintype of Three Union Cavalrymen – Two Wearing Corps Badges

$4751/6 Plate Tintype of Three Union Cavalrymen – Two Wearing Corps BadgesJune 5, 2025 -

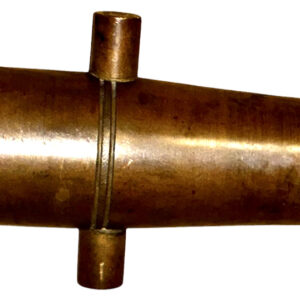

Mid-19th Century Civil War Period Cast Brass Diminutive Cannon Tube (Model)

$275Mid-19th Century Civil War Period Cast Brass Diminutive Cannon Tube (Model)June 5, 2025 -

Significant Group of Civil War Officer’s Shoulder Boards, Hat Badges and Various Officer and Enlisted Man’s Insignia

Significant Group of Civil War Officer’s Shoulder Boards, Hat Badges and Various Officer and Enlisted Man’s InsigniaJune 1, 2025 -

Pre-Civil War Period Id’d Beaver Stovepipe Hat in its Original Box – Id’d to Brig. General George Williamson Balloch

$850Pre-Civil War Period Id’d Beaver Stovepipe Hat in its Original Box – Id’d to Brig. General George Williamson BallochMay 31, 2025 -

Id’d Civil War Camp Trunk – Jason Morse, Adjutant of the 111th USCT

$1,750Id’d Civil War Camp Trunk – Jason Morse, Adjutant of the 111th USCTMay 30, 2025